ASME-Bemalung aus Kohlenstoffstahl

Produktübersicht

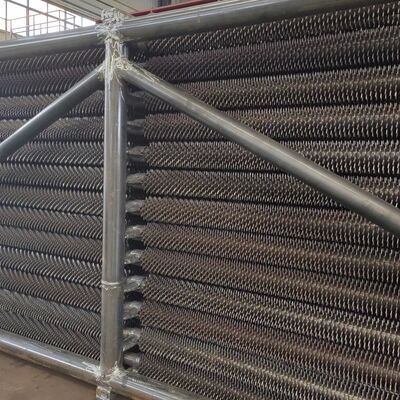

Das Flossenrohr ist ein spezielles Wärmetauscherelement, das zur Maximierung der thermischen Effizienz entwickelt wurde.mit einer höheren Wärmeübertragungsleistung.

Schlüsselfunktionsmerkmale

- Korrosionsbeständigkeit:Eine spezielle Korrosionsschutzbeschichtung an den Innenwänden und rostfeste Außenbehandlungen sorgen für eine ausgezeichnete Korrosionsbeständigkeit und eine längere Lebensdauer

- Verbesserte Verschleißfestigkeit:Wandstärke in der Regel größer als 3,5 mm, mit anpassbaren Spezifikationen, um spezifische Anforderungen an die Verschleißfestigkeit zu erfüllen

- Niedrige Wärmebeständigkeit durch Berührung:Spiralflossen maximieren den Kontaktbereich mit der Luft und minimieren den Wärmewiderstand für eine optimale Wärmeübertragung

- Staubschutz:Ein technisches Design verhindert Staubansammlung und erleichtert die einfache Wartung der Reinigung

Produktspezifikationen

- Flossenröhrentyp:Rund, quadratisch, rechteckig, oval, mit Flossen

- Oberflächenbehandlungen:Aufbereitung und Veredelung

- Flossenhöhe:Nach Maß angepasst

- Verpackung:Holzkästen, Paletten

- Anwendungen:Boiler, Wärmetauscher und Kondensatoren

- Materialoptionen:Rohre aus Kohlenstoffstahl, aus Edelstahl

Technische Parameter

| Parameter |

Beschreibung |

| Flossenhöhe |

Individualisiert |

| Stärke |

Individualisiert |

| Paket |

Holzkästen, Paletten |

| Länge |

Individualisiert |

| Flossenhöhe |

Individualisiert |

| Anwendung |

Kessel, Wärmetauscher, Kondensator, Wärmetauscher für Kesselrohr |

| Material |

Kohlenstoffstahl, Legierstahl, Edelstahl, Kupfer, Aluminium |

| Größe |

Individualisiert |

| Form |

Rund, quadratisch, rechteckig, oval, mit Flossen |

| Standards |

ASME, ASTM, EN, JIS, DIN |

Anwendungen

HD Boiler Fin Tube ist ein hochwertiges Rohr aus Kohlenstoffstahl, das für anspruchsvolle Anwendungen in Kesseln, Wärmetauschern, Kondensatoren und Flossen- und Rohrwärmetauschersystemen entwickelt wurde.Hergestellt nach ASME, ISO9001:2015, und ISOEN3834-Standards, sind diese Rohre in maßgeschneiderten Größen und Dicken erhältlich, um spezifische Kundenanforderungen zu erfüllen.

Informationen zur Bestellung:Mindestbestellmenge: 3 TONNEN. Die Preise sind verhandelbar. Die Lieferzeit variiert je nach Menge. Zahlungsbedingungen: 30% nach Vertragsabschluss, 70% vor Versand oder 100% L/C auf Sicht. Lieferkapazität: 100 Tonnen/Monat.

Verpackung und Versand

Jede Kesselflossenröhre ist individuell mit Kartonhüllen geschützt und in Holzkisten oder Kartons sicher verpackt.Die Paletten sind mit wasserdichten Plättchen bedeckt, um die Unversehrtheit des Produktes während des Transports zu gewährleisten.Die Versandmethoden sind auf die Bestellgröße zugeschnitten: kleine Pakete über UPS oder FedEx, größere Sendungen über Frachtunternehmen einschließlich R&L Carriers oder Estes Express.

Profil des Herstellers

Hua Dong Boiler Co., Ltd. ist ein etabliertes Hightech-Unternehmen, das sich seit 1985 auf die Herstellung von Kesseln spezialisiert hat. Mit zwei Produktionsstätten mit einer Fläche von 400.000 m2 und einem Anlagevermögen von 110 USD000,000, beschäftigt das Unternehmen 1.100 Mitarbeiter, darunter 150 Techniker und 600 zertifizierte Schweißer.

Zertifizierungen:Lizenzen für Kessel der Klasse A und Druckbehälter der Klasse A1 und A2 der Chinesischen Generalverwaltung für Qualitätsüberwachung; ASME-Stempel "S", "U" und "NB"; ISO9001, SO3834,EN12952 Zertifizierung des Qualitätsmanagementsystems.

Häufig gestellte Fragen

Was ist ein Boiler Fin Tube?

Ein Boiler Fin Tube ist ein spezialisierter Wärmetauscherkomponent, der in industriellen Kesseln, HVAC-Systemen und verschiedenen Wärmeübertragungsgeräten weit verbreitet ist.

Welche Marke ist HD Boiler Fin Tube?

HD Boiler ist der etablierte Markenname für unsere Produkte aus Boilerflossenröhren.

Wo wird HD Boiler Fin Tube hergestellt?

HD Boiler Fin Tube wird in China hergestellt.

Welche Zertifizierungen besitzt HD Boiler Fin Tube?

Unsere Produkte sind nach ASME, ISO9001 zertifiziert:2015, und ISOEN3834-Normen.

Was ist die Mindestbestellmenge?

Die Mindestbestellmenge für HD Boiler Fin Tube beträgt 3 TONNEN.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!